Aluminum & Magnesium Head Expanders

Product Overview

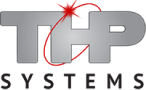

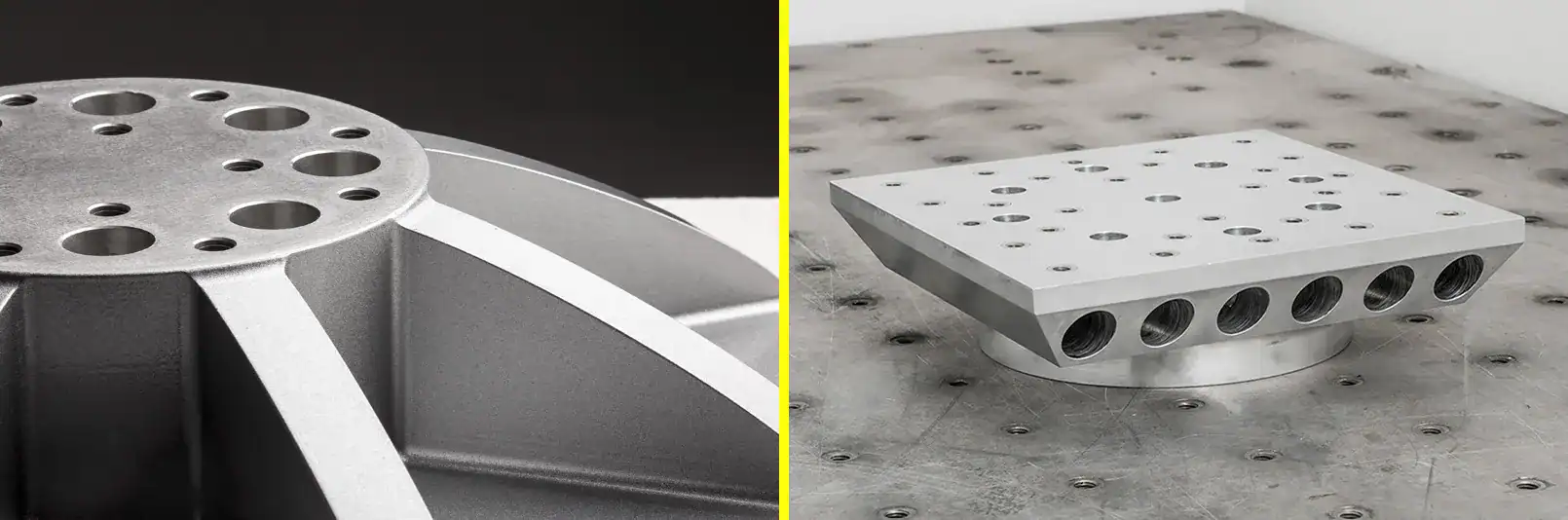

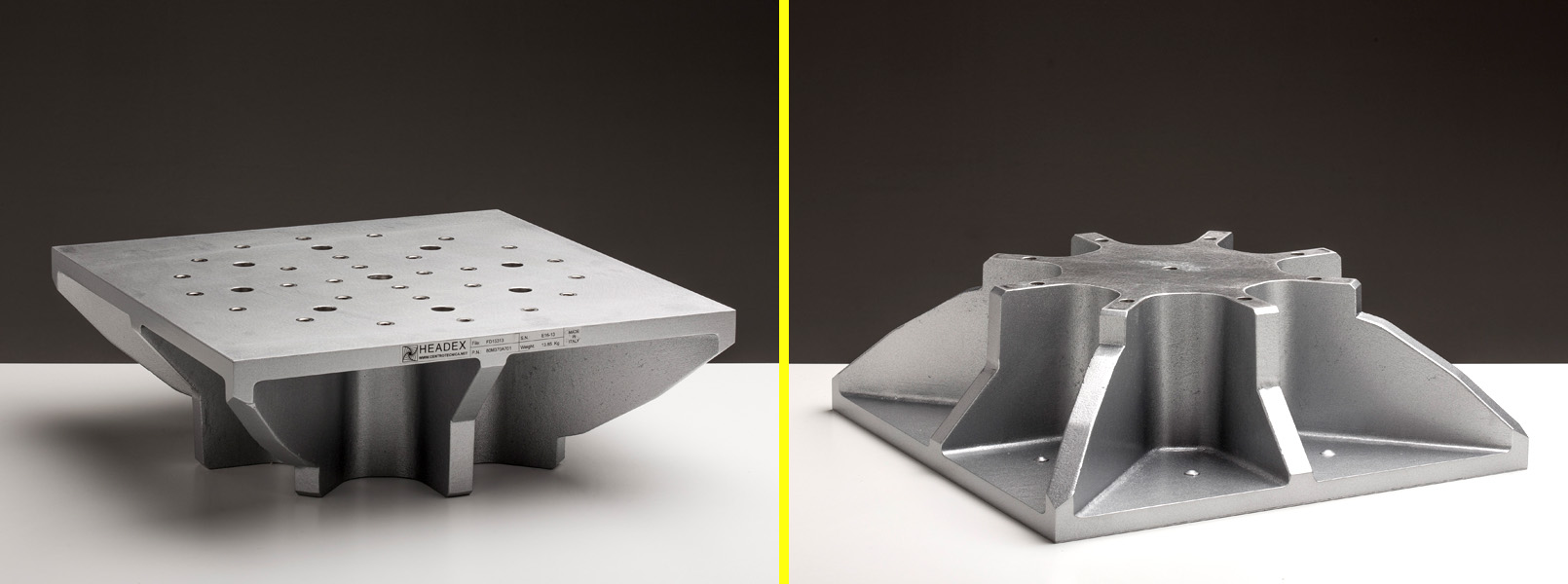

Designed for High-Frequency testing, Head Expanders can be made from either Magnesium or Aluminium. Head Expanders that are cast, are lighter and offer high resonance frequency.

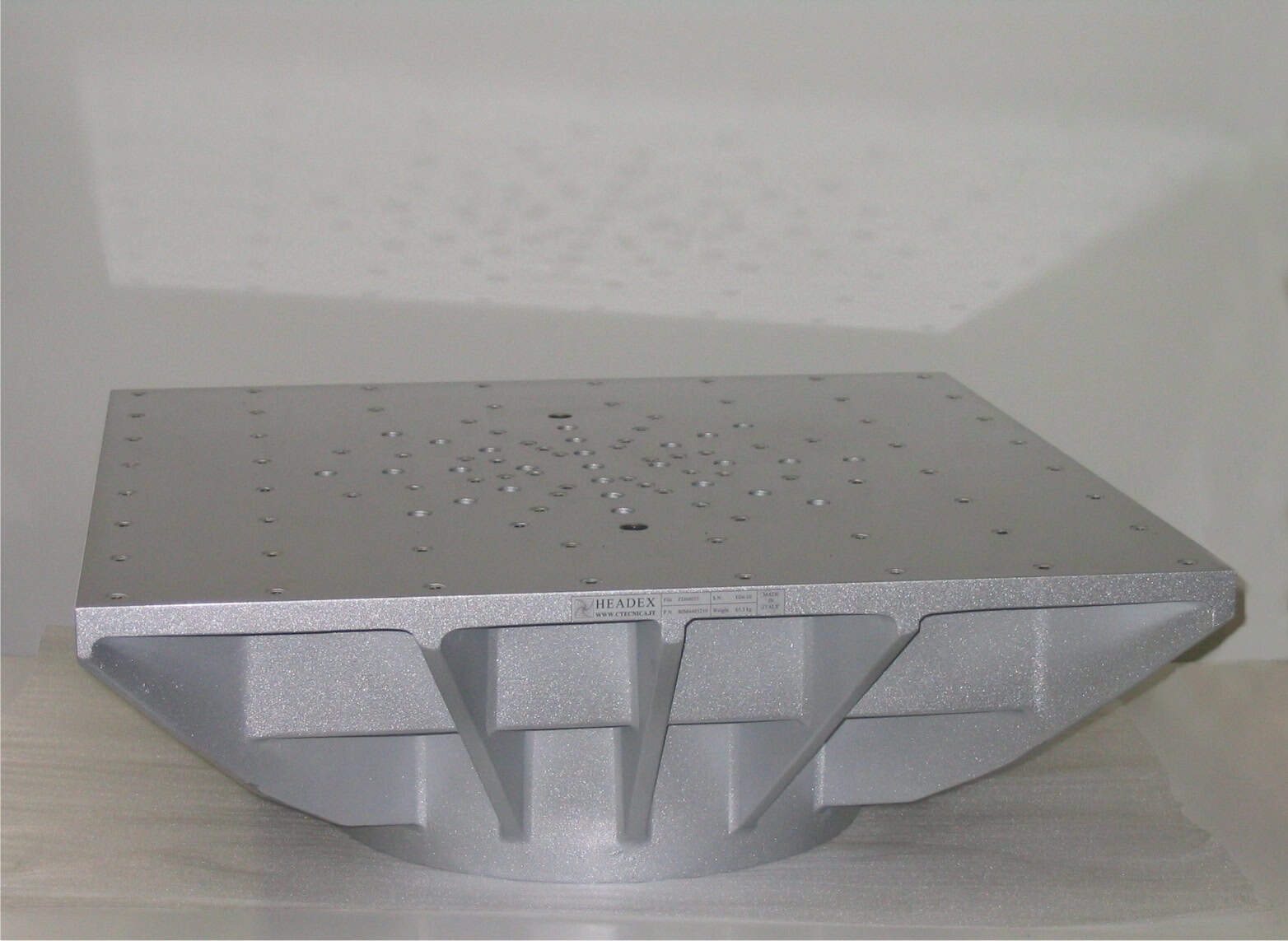

Machined Head Expanders can be made from a solid Magnesium or Aluminium plate. Machined Head Expanders have a lower frequency rage, but offer more weight savings when compared to a cast Expander.

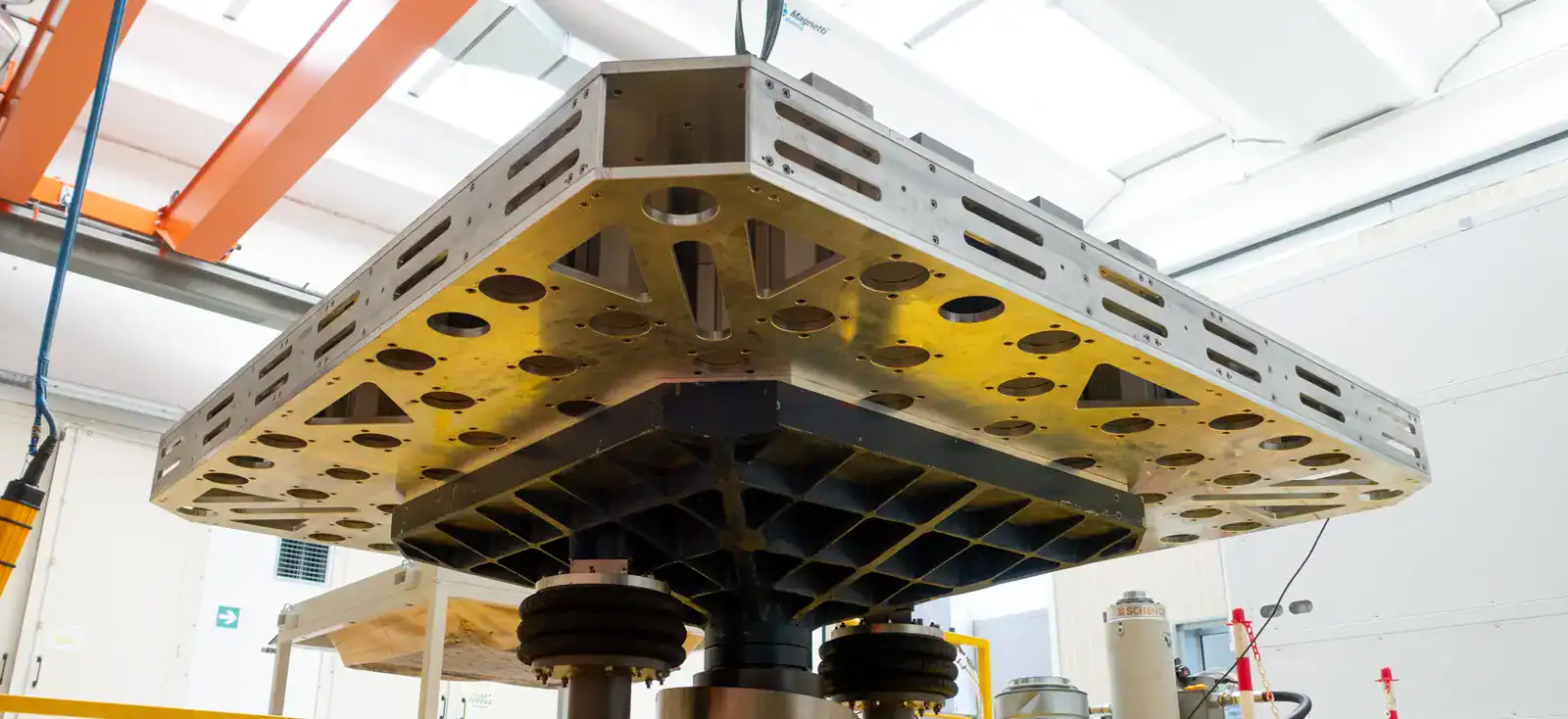

Boxed Head Expanders are created by assembling aluminium or magnesium plates with a special technique. This is the best-in-class Head Expander for a Low Frequency Range.

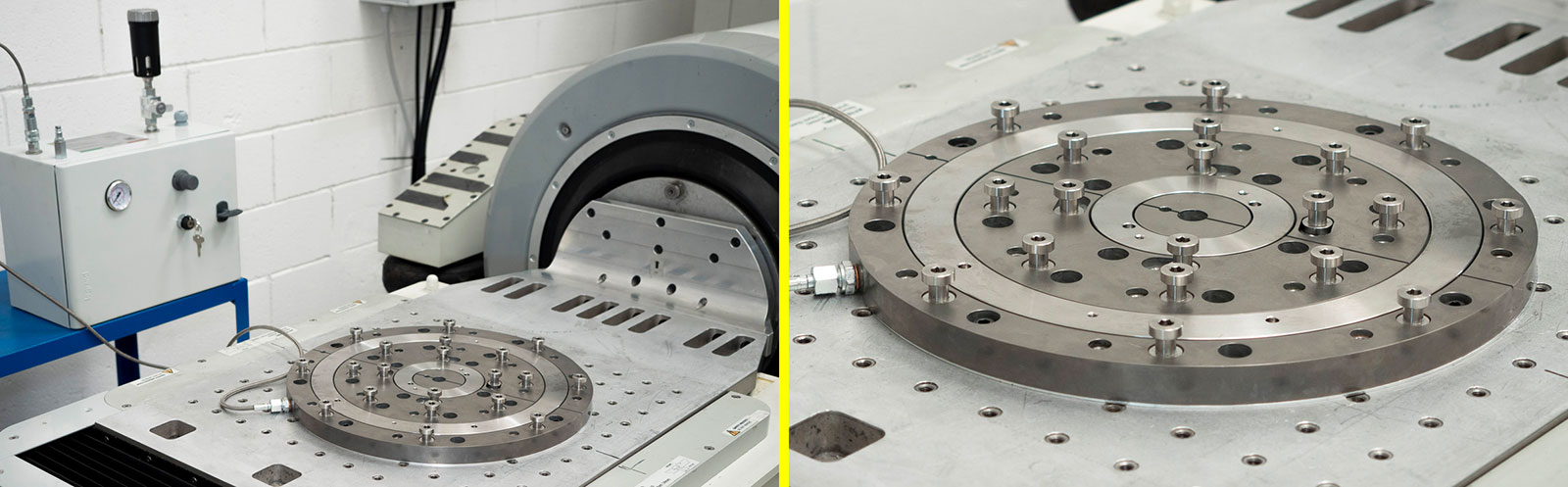

The purpose of a Head Expander is to allow testing of multiple items simultaneously, or expanding the test area of a shaker for larger test samples.

Head Expanders can increase efficiency, or simply expand your test capabilities on an existing Vibration Test System.

To select the correct Head Expander for your project, you should look at the following factors:

- Sample Size

- Maximum Frequency Required

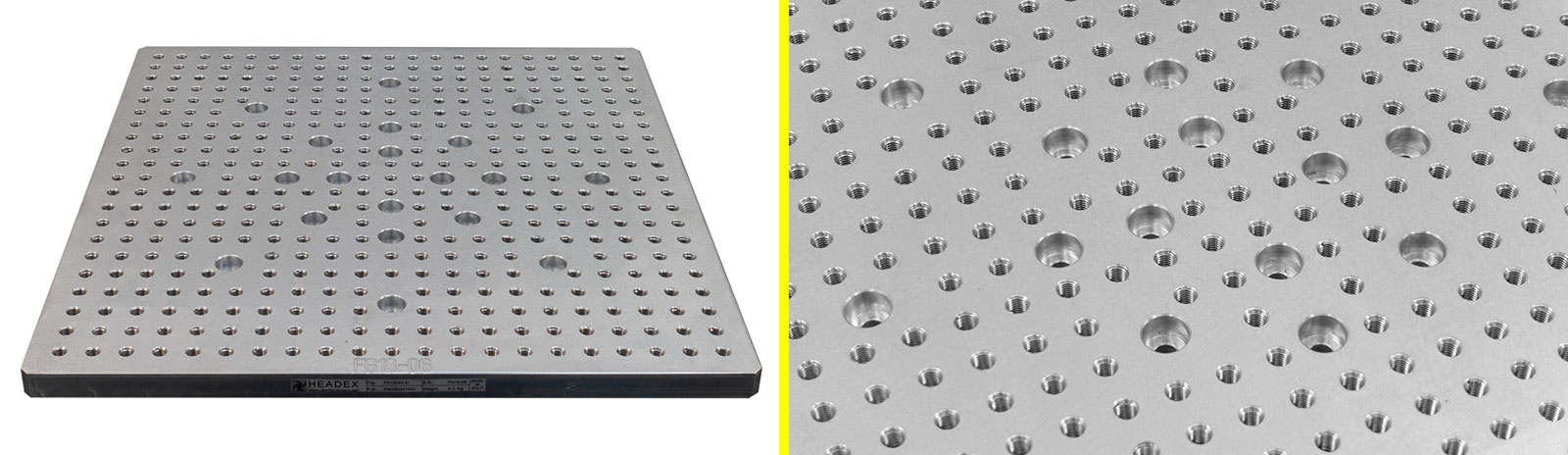

Magnesium Head Expanders from Centrotecnica are available with standard or customized insert-patterns.

Key Features

The choice of production materials is guided by the need to save weight.

ALUMINIUM HEAD EXPANDERS: these are by far the most popular because of the lightness, low cost and ease of processing of this metal.

MAGNESIUM HEAD EXPANDERS: they are significantly lighter but have a similar dynamic behaviour to aluminium head expanders. Magnesium, however, is a more expensive metal and more difficult to machine, which is why it is only used in cases where limiting the head expander’s mass is a must.

Strong points of a head expander

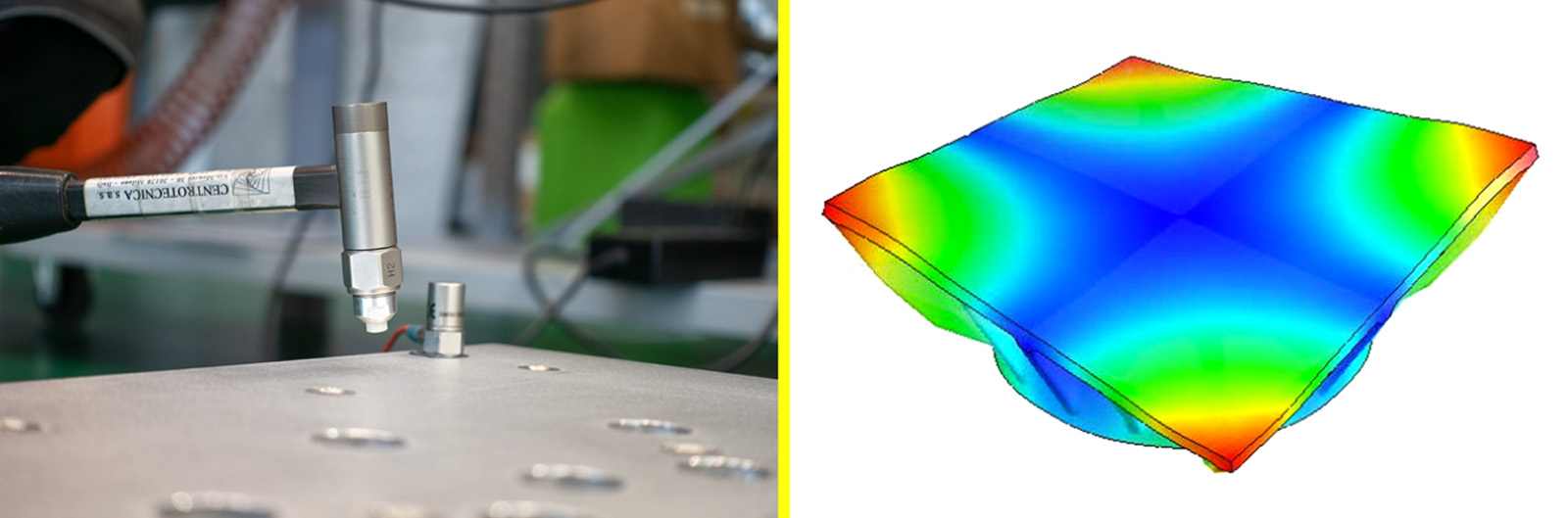

DYNAMIC BEHAVIOUR: low level of resonances in the test frequency range. Resonance frequencies can seriously affect the correct performance of the test.

LIGHTWEIGHT: weight savings result in greater efficiency and improved shaker performance.

- High and low Frequency

- Standard range of un guided Expanders to suit most manufacturers Vibration test Systems

- Dimensions of up to 3000 mm available

- Full inspection and dynamic test report with each expander delivered

Options

Complementary accessories to expanders

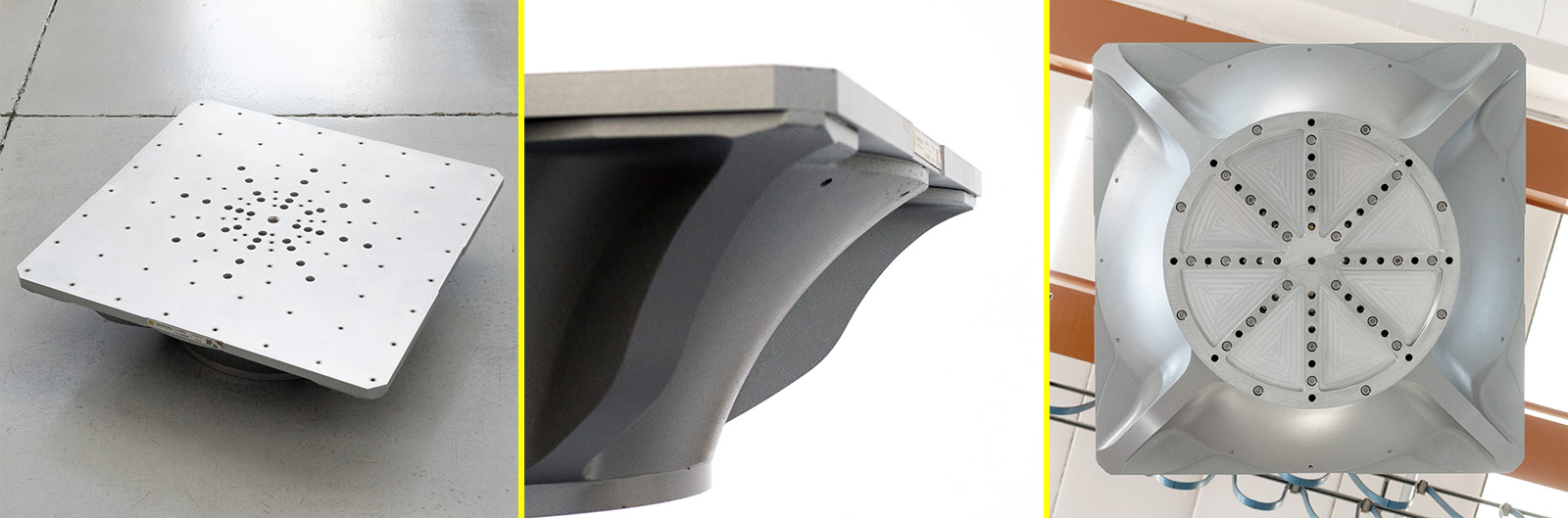

Damping: this is a thin, lightweight plate that is intended to dampen resonance vibrations.

Interface plates: for adapting fixtures or samples to the head expander’s drilling mask.

Instant Clamp: patent-pending product of great added value in economic and practical terms. It makes it simple and ultra-fast (less than 30 seconds) to mount or change the axis of the fixture to the shaker, slip table or head expander.

- Bespoke guidance systems for payloads with high overturning moments

- Thermal Barriers for use with climatic chambers

- Expanders for Servo Hydraulic actuators

Inspections and Certifications

All head expanders from Centrotecnica are delivered with technical reports attesting to their high production standards.

Modal analysis: head expanders are tested by means of the hammer test to identify resonance frequencies and the best control strategies. The results are reported in the test report.

Precision Starts Here