- Shorter development times

- Increase in product quality

- Avoidance of after works

- Avoidance of returns

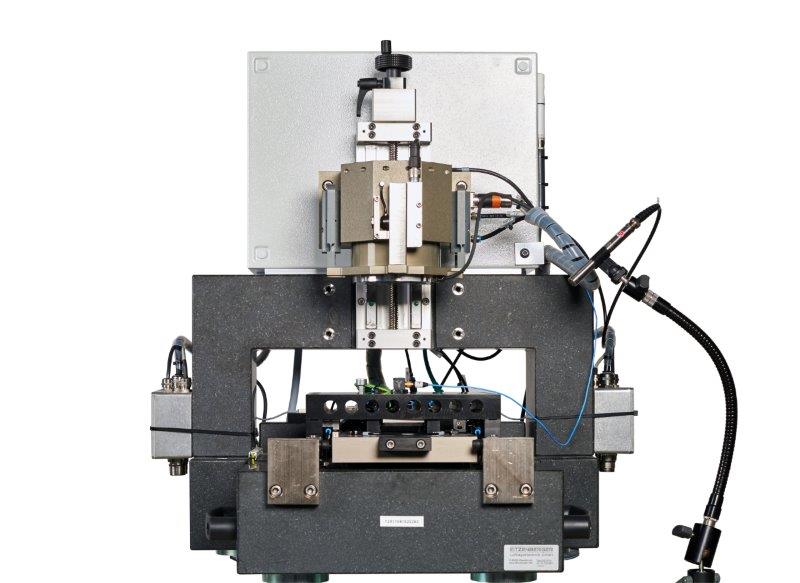

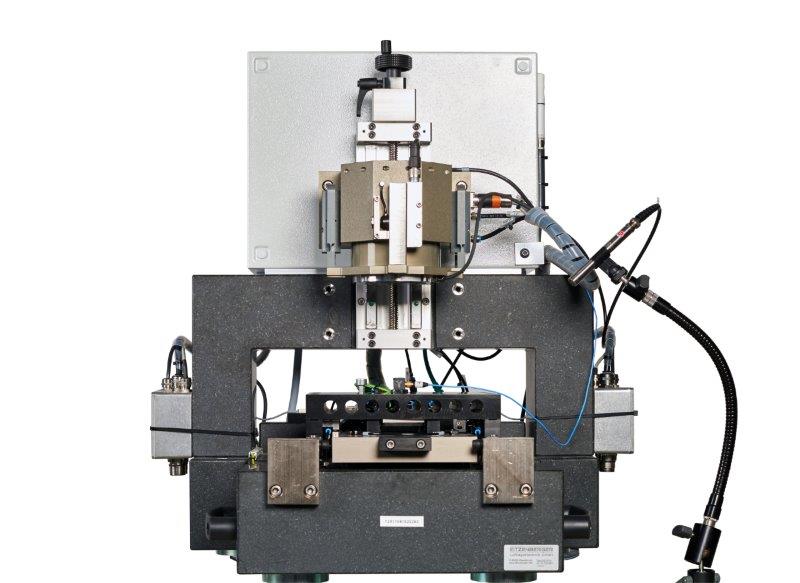

Korema Test Bench

Product Overview

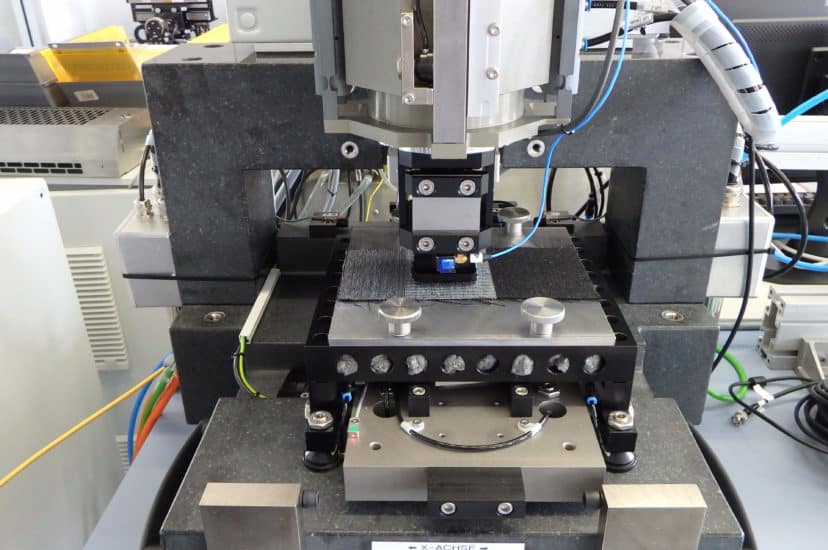

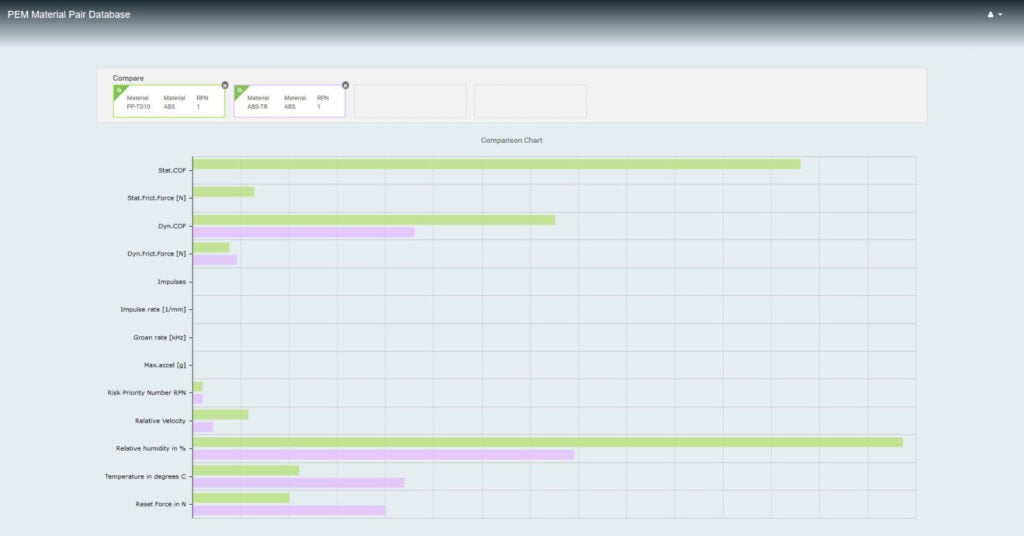

Noises due to friction can have a very unpleasant psycho-acoustic effect on humans, which has a direct effect on a negative assessment of the perceived quality of the final product. However, friction noise can also lead to functional disorder. Contact pairs are for example skin to fabric, fabric to fabric, skin or fabric to third contact materials.

In addition, friction noise as it occurs in vehicles can be investigated, whereby these can be road-related or function-related. The test stand makes it possible to verify and evaluate acoustically emitted noises.

The focus is not only on the material properties like friction/stick-slip of material pairs such as fabric to fabric (or to other materials), but also on the acoustically emitted noise.

Currently, there is no test stand available that meets the above-mentioned goals. The previous stick-slip test rigs only tested material properties. The simultaneous detection of the acoustically emitted noises is a total new development.

Markets

Technical Specifications

Effective measuring friction – 100 mm x 100 mm

Static and dynamic friction force – t.b.d.

Speed of the table (2 dimensional) – ≤ 200 mm/s

Normal face – ≤ 40 N

Suitable temperature range – t.b.d.

Acceleration – ≤ 14 m/s² (preliminary)

Key Features

Benefits –

Options

The focus is not only on the material properties like friction/stick-slip of material pairs such as fabric to fabric (or to other materials), but also on the acoustically emitted noise.

Currently, there is no test stand available that meets the above-mentioned goals. The previous stick-slip test rigs only tested material properties. The simultaneous detection of the acoustically emitted noises is a total new development.

Videos

Precision Starts Here