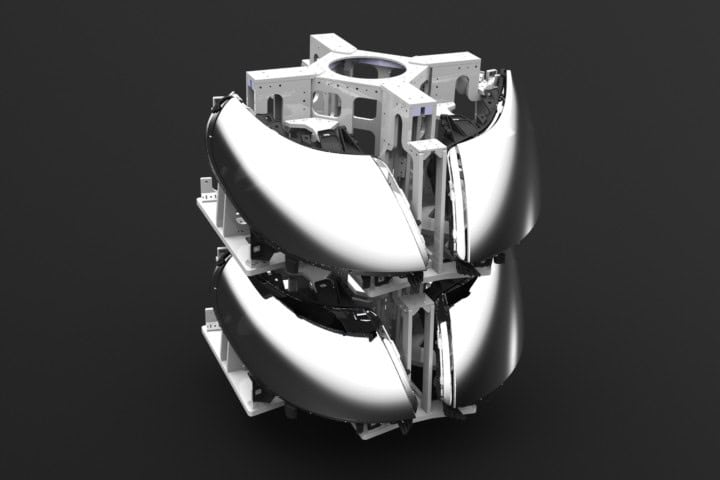

Custom Fixtures

Product Overview

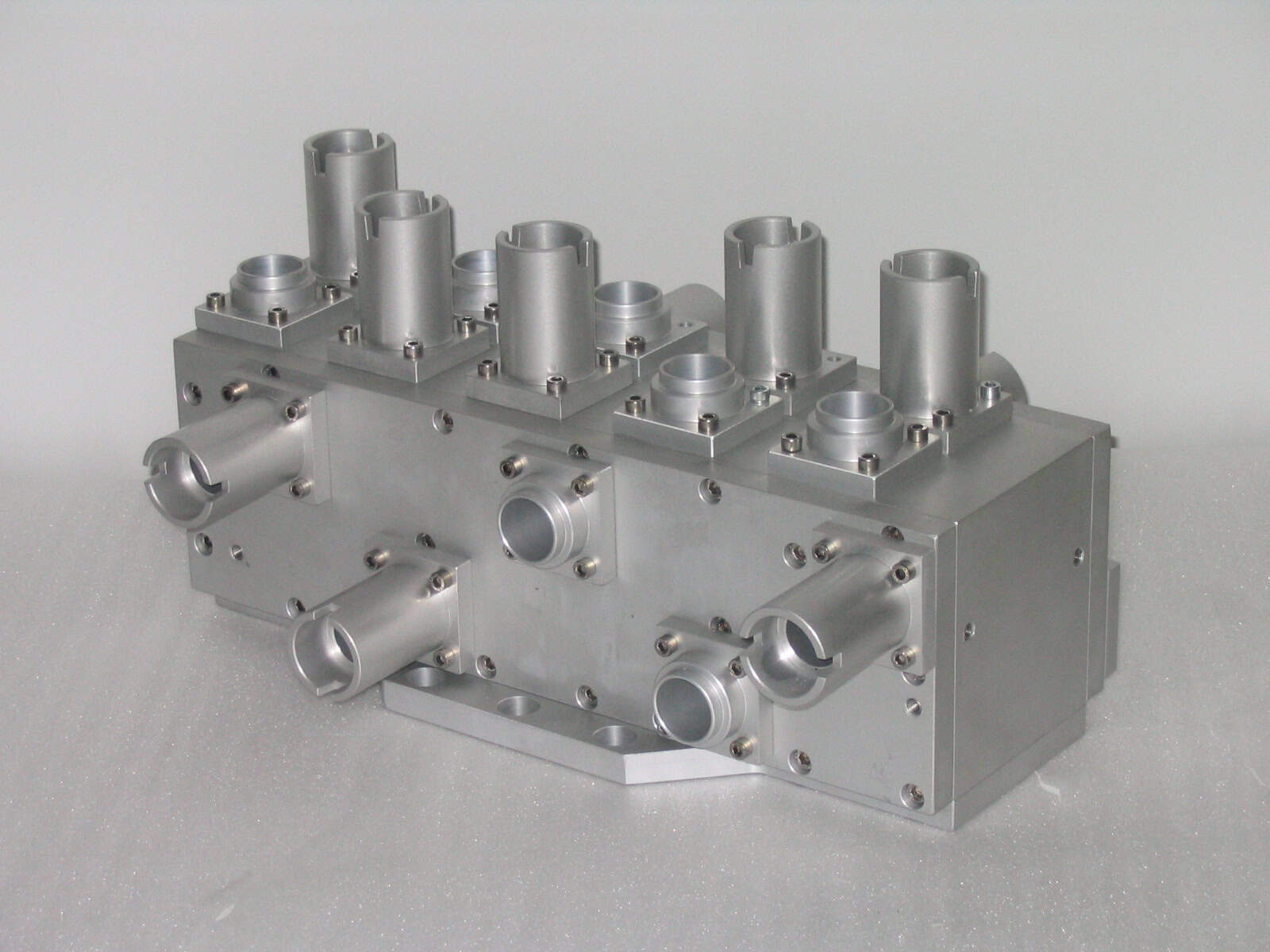

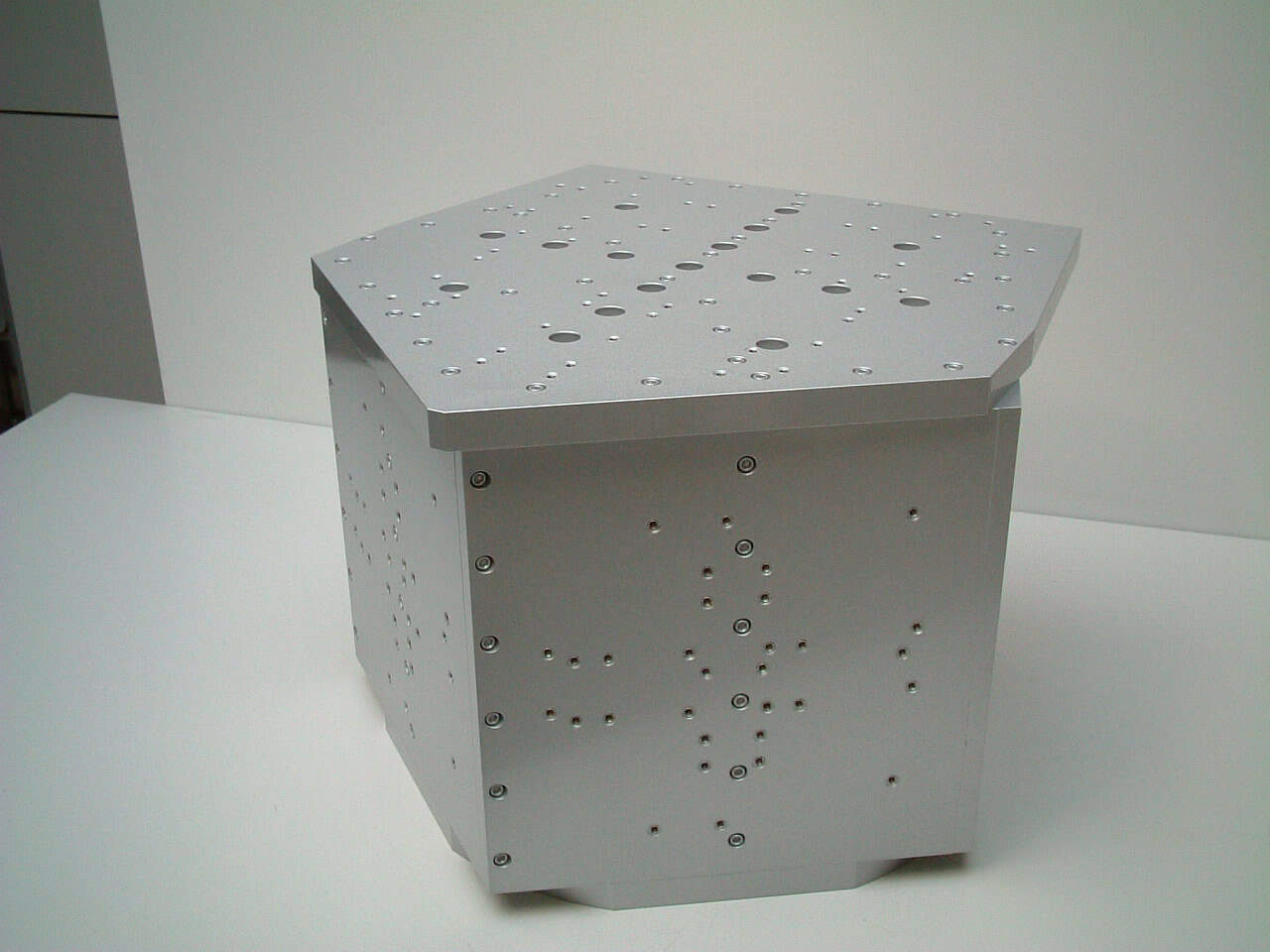

All our fixtures are design and customized to suit customers’ requirements for any payload.

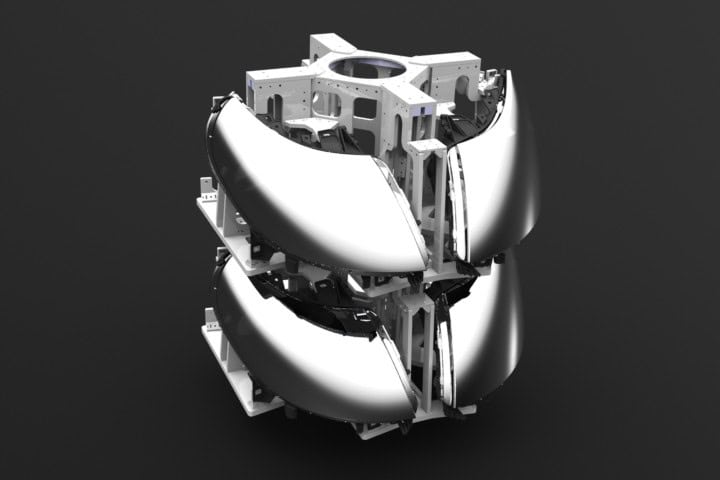

Professional engineers will design, develop and create custom fixtures, designed to represent realistic scenarios.

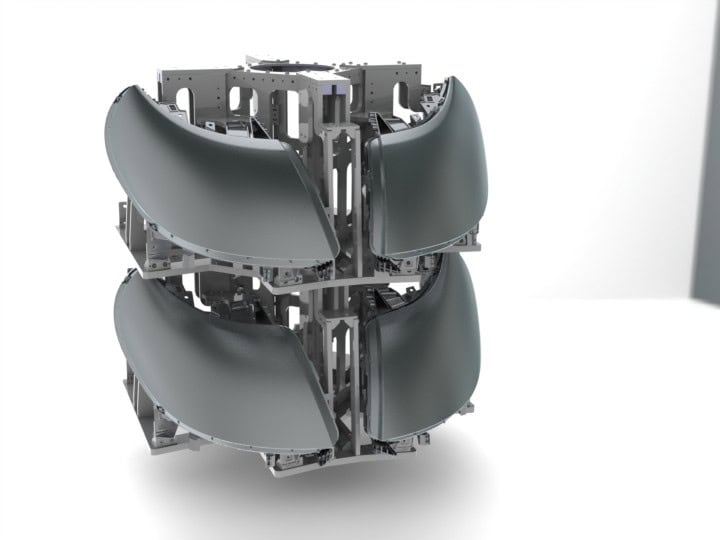

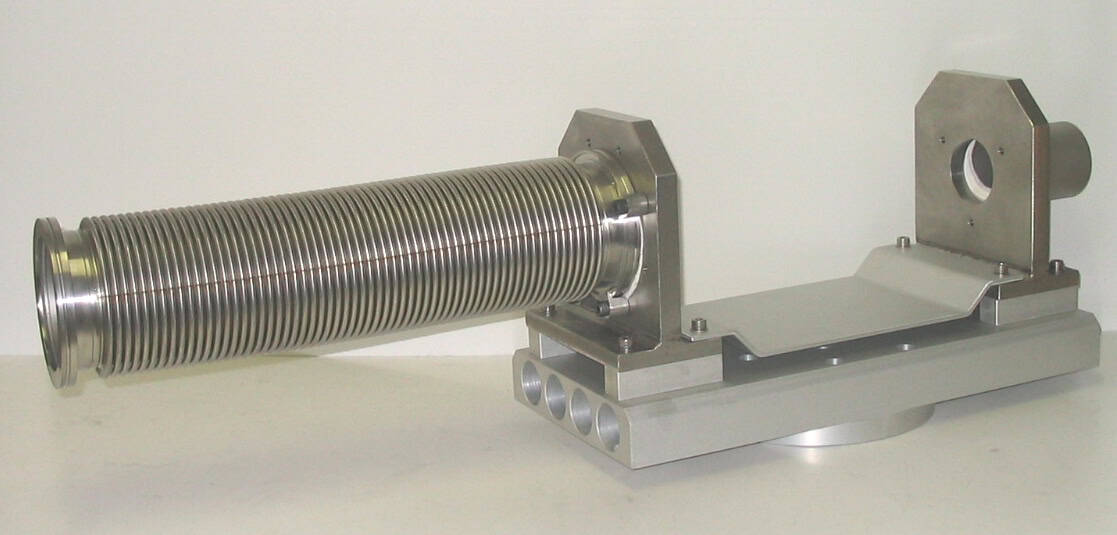

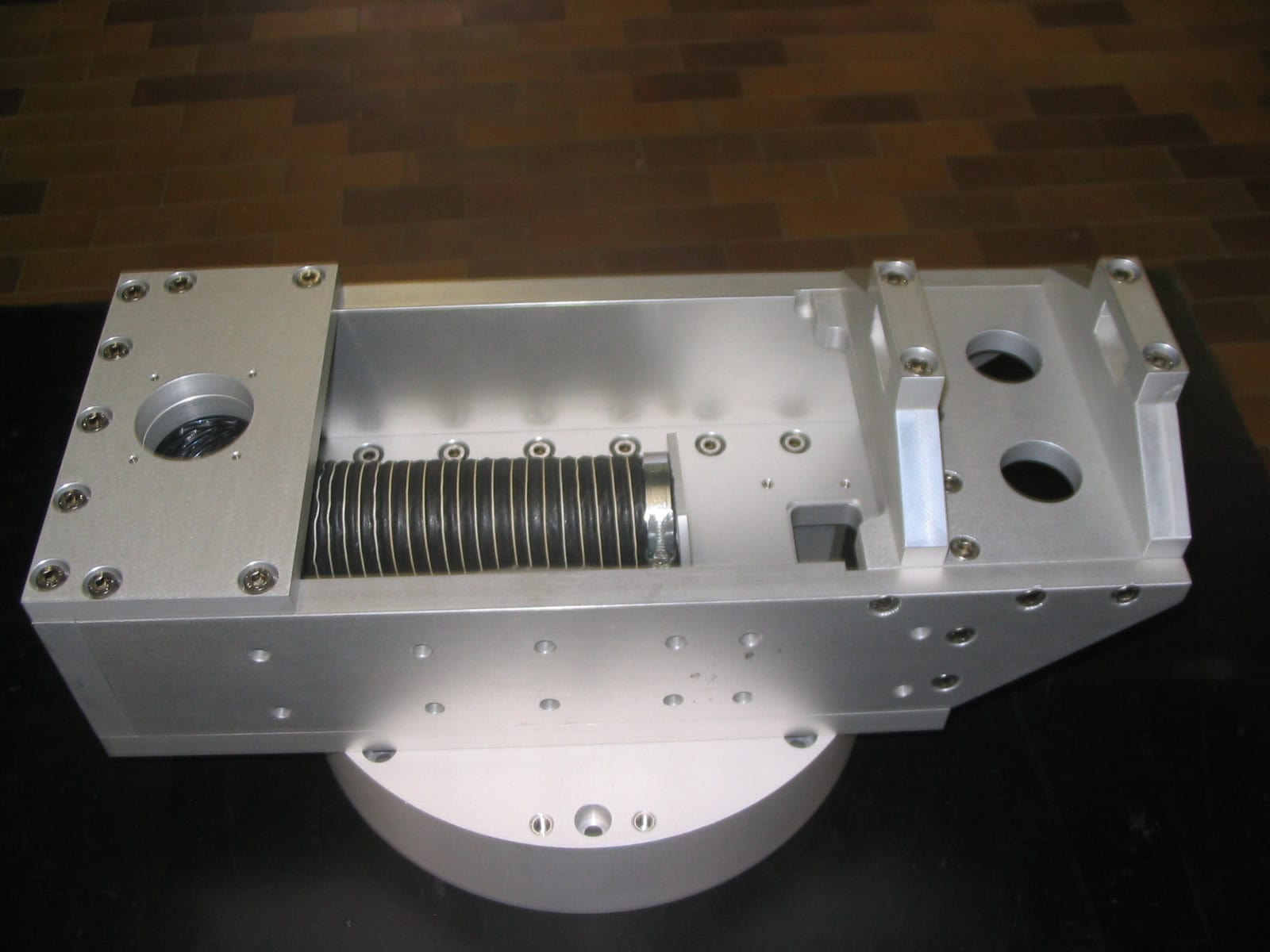

All customized fixtures are designed to be lightweight, while maintaining a high-degree of durability and stiffness. If required our fixtures can be rotated and mounted along three axis, giving the end-user flexibility and efficiency due to reduced setup as the same fixture can be used for different tests.

Custom Fixture projects start with the item drawings, number of items to be tested, vibration data and test profile.

Finally, Finite Element Analysis (FEA) and QA testing is performed on all the fixtures. The fixture will be dispatched after sign-off and approval from the customer with a technical report.

Markets

Technical Specifications

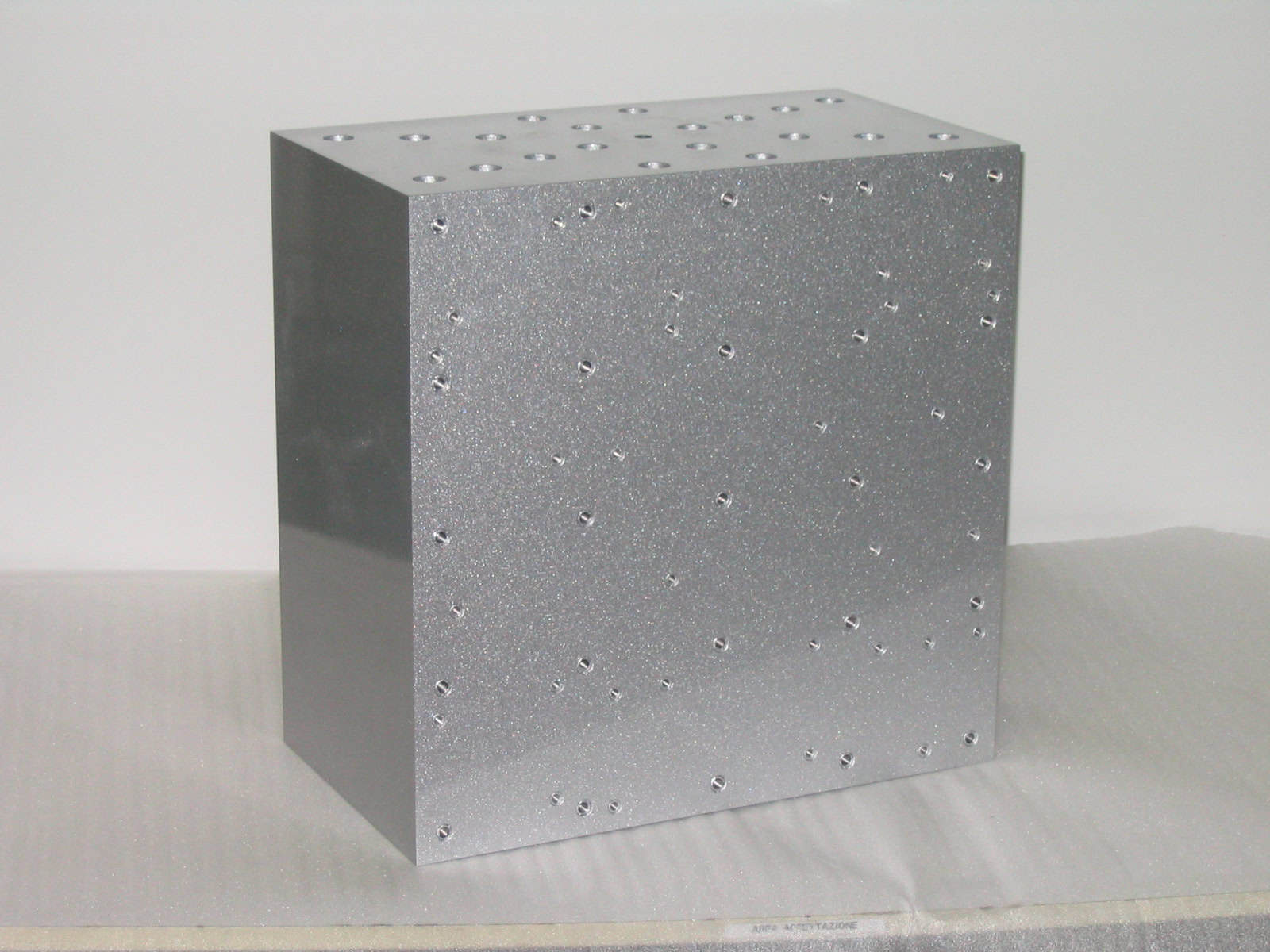

The most important technical feature of a fixture is the amount of resonance frequencies in the range of use for which it is intended. All our fixtures are delivered with documentation certifying their high production standards:

Dimensional validation: the extremely low dimensional tolerances with which our fixtures are produced are guaranteed by measurements made with a 7-axis 3D measuring arm. Inaccurate dimensions may lead to difficulties or impossibility of sample assembly.

Resonance search: fixtures are tested on a shaker table to identify resonance frequencies and the best control strategies, which are reported in the test report.

Key Features

- Customised to the customer’s specific needs.

- All fixtures run through FEA and QA testing to ensure quality.

- Full set of actual Dynamic Test results provided

Configuration

General qualities:

- optimal dynamic behaviour in the test frequency range.

- ease of set-up: mounting of sample, accelerometers and test axis change operations must be easy.

- longevity: no cracks, breaks or deformations should occur even after very long use.

- lightness: saving weight leads to greater efficiency and optimises shaker performance. To reach this goal, we have acquired the necessary know-how for the production of magnesium fixtures.

Options

- Modification and improvement to existing Customer fixtures

- Other Test equipment fixtures available for Drop and Shock Machines

Precision Starts Here