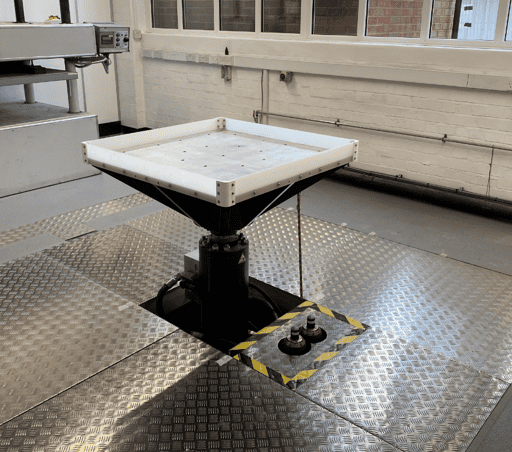

HV-Series: Hydraulic Vibration Testers

Product Overview

Hydraulic Vibration Test Systems for package and product reliability testing. For performance testing of products and shipping containers.

L.A.B.’s Hydraulic Vibration Test Systems help you design high quality, cost-effective products and shipping containers by accurately measuring sensitivity to sine or random vibrations. Field-Test Systems are specifically designed to meet a wide range of ASTM, DOT, ISTA, 3A, ISO and federal standards for vibration testing. Our hydraulic vibration test systems are ideal for a wide spectrum of testing applications ranging from sine sweep tests to the most complex data real time simulation, or random reproduction applications.

Hydraulic Vibration Systems perform the repetitive bounce, sine sweep, resonance search and dwell, and random vibration tests that help you:

-

Design package systems that survive the distribution environment

-

Identify components susceptible to fatigue failure

-

Reduce package material costs

-

Minimize shipping damage claims

-

Cut warranty expenses

Markets

Models

- HV-24

- HV-36

- HV-48

- HV-60

- HV 72

- HV 90

Product Resources

Technical Specifications

Key Features

What Is A Hydraulic Vibration System?

- An L.A.B Hydraulic System is a rigid table surface supported and driven by a closed-loop servo controlled hydraulic actuator.

- The system is capable of producing single axis vibration at controlled levels of displacement, velocity or acceleration throughout a specific range of frequencies.

Standard System Components

- Vibration Table

- Actuator/Piston Assembly

- Hydraulic Power Supply

- Hydraulic Manifold

- Servo Valve

- LAB Motion Controller HSC Servo Controller

- Lynx™ Digital Vibration Control System

- 1-G Supports (48” and Larger)

Vibration Table

- Actuator/Piston Assembly

- Hydraulic Power Supply

- Hydraulic Manifold

- Servo Valve

- LAB Motion Controller HSC Servo Controller

- Lynx™ Digital Vibration Control System

- 1-G Supports (48” and Larger)

Hi-Performance Tables

- Aluminum alloy or magnesium table weldments provide the most rigid tables for higher frequency testing and superior uniformity, unmatched in the industry.

Accumulator Assembly

- Pressurized gas bladders help provide a constant and smooth supply of fluid to the actuator.

1-G Supports (as needed)

- Reduces load on actuator by 1g of acceleration. Also provides anti-rotation of table during operation. Not used on smaller tables.

Hydrostatic Bearing Actuator

- State-of-the-art hydrostatic bearing actuators are self-centering, with no piston rings or hi-pressure seals providing long-life with little maintenance. This means unsurpassed control & balance for off-centered loads.

Servo Valve

- We use industry standard valves to regulate how much (displacement) and how fast (frequency) high pressure fluid needs to flow through the actuator.

Reaction Mass

- Solid steel mass mounted on a damped air-mount suspension provides highest possible system stability and minimal velocity loss at low frequencies.

Air Bag Isolators System

- Isolates vibration between the system and your foundation during operation.

Performance

- Down to 1Hz, up to 500Hz.

Configuration

Installation of L.A.B HV Systems

As L.A.B HV Vibration systems are varied in capabilities and intended use, so will the installations. Systems being installed in Asia, the USA or Europe all will have different facility, safety and usability constraints. L.A.B Equipment will guide you through the process to make sure your installation is the best it can be.Will will guide you through the process giving you the details you need regarding:

Flooring Requirements

Utility Requirements

Spacing and optimum workspace

Mounting the equipment

Safety requirements

Equipment and tools needed by the customer for installing and positioning the equipmentOptions

Test Fixture

- Set allows easy specimen attachment to the vibration table.

Stacking Fences

- Maintain shipping container alignment during testing.

Custom Systems

- heavier payloads

- larger displacement or velocity

- broader frequency range

Precision Starts Here