Models

Specifications

Click HereControl System

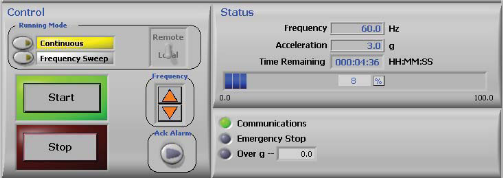

Operation is performed through L.A.B’s exclusive Advanced Machine Control Plus (AMC+), a Windows based control and display software package.

Select either continu-ous vibration or a frequency sweep mode. In continuous vibration mode, select the frequency level, maximum acceleration limit, and run duration. In frequency sweep mode, select the lower and upper frequency limits, cycle period, maximum acceleration limit and run duration.

In either mode, the user calculates the displacement with a known frequency and acceleration and then manually adjusts counter-weights on the vibration table to deliver the calculated displacement.

Advanced Machine Control

- Designed for Vibratest Series vibration tables

- Windows 8 software

- Includes interlock for external chambers (start/stop)

- Includes run duration timer with auto-stop function

Control and status panel

Includes:

- Software Installation CD

- 50 G Accelerometer with Cable

- Interface Cables

Key Features

- Reaction type machine performs vertical sinusoidal test.

- Test Frequency is infinitely adjustable between 8 and 60 Hz under operation.

- Various combinations of frequency and displacement can be configured to result in up to 3.2G or 10G acceleration.

- Self contained, built in isolation system eliminates the need for special foundations.

- Advanced design pneumatic system provides low frequency isolation and payload stability that is far superior to steel spring isolators.

- System displacement is manually adjustable.

- Once set, displacement is maintained at a constant level regardless of the test frequency.

- Standard utility requirements: 70-psi air for suspension adjustments (low volume).

Basic Configuration

- Windows XP™ Advance Machine Control AMC+(PC not included)

- Perform to AGREE testing requirements

- Self contained, built-in air isolation system

- Manually adjustable vibratory displacement

- No special foundation required

- Frequency adjustable between 8-60Hz

- Many table sizes to choose from

Available Options

- Insulated table top

- Casters

- Height Risers

- Track

- Diaphragm Support Brackets

- 10 G Rating

- Non-Standard Voltage

- CE Compliance

- Stainless Steel Drip Pan

Resources

Request Quote

Please select the form below relevant to your enquiry:

VibraTest Mechanical Vibration Testers

VibraTest Mechanical Vibration Testers