ACS Airbag Test Chamber

Product Overview

ACS chambers to test airbag systems are designed to carry out standard tests required by major regulations. By means of high speed cameras, every instant of the airbag deployment can be recorded.

The chamber can be equipped with a high speed opening and closing door system for quick deployment of the specimen on a dedicated frame. As an alternative, several windows can be installed on one side of the chamber and the high speed cameras can be installed right in front of them. Parameters of temperature and humidity are set inside the chamber to obtain the desired conditions.

Markets

Product Resources

Key Features

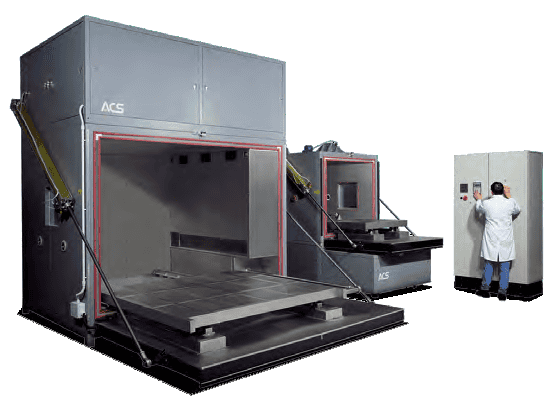

Example of a chamber built according to customer specifications.

- Internal Dimensions: 2000x2000x2000 mm (LxDxH)

- External Dimensions: 2300x4700x2550 mm (LxDxH)

- Working capacity: 8000 l

- Temperature range: -40°C / +95°C

- Rate of temperature change:

- 3°C/min from -40°C to +95°C

- 3°C/min from +95°C to -40°C

FEATURES:

The chamber is provided with:

- Door with automatic opening, horizontal sliding and pneumatic safety system with opening time: 10 sec.

- Automatic airbag activation system, with horizontal internal/external chamber movement in 7 sec.

Options

ACS can provide customized solutions that are adapted to the requests of every customer. Thanks to its accurate analysis of testing needs and highly specialized technical consultancy, ACS designs and manufactures environmental simulation chambers in the configuration most suitable for meeting the customer’s testing needs.

Videos

Software

The software for this type of chamber is an application that includes all the functions based on the specifications requested by the customer. The chamber has a built-in control panel for controlling and managing its functions. The chamber can also be controlled remotely using the WinKratos software or an equivalent application.

Precision Starts Here