ACS Dry Corrosion

Product Overview

ACS Dry Corrosion chamber incorporates the new approach to corrosion diagnostics (DCTCTM) which has overcome the traditional concept of “salt spray chambers”.

Corrosion is a chemical or electrochemical reaction between a material and its environment. This process causes the deterioration of the product and the loss of its initial characteristics.

Climatic chambers for corrosion testing can help predict the resistance of materials in order to estimate the life cycle of the components, compare different products and evaluate the behavior of a coating in a specific corrosive environment.

Extremely reliable, the chamber allows to study the specimens undergoing incisive stress such as “scab” and “filiform” corrosion. are completely made of plastic anti-corrosion materials ensuring endurance and perfect seal over time.

All the models are equipped with a PLC-based control system. ACS powerful remote control software, WinKratosTM, is available as option both for single chamber and multichamber (no. 16 max) management.

Markets

Models

- 600 PN

- 1200 PN

- 2300 P

Product Resources

Technical Specifications

1. +280mm at the cover top

2. +310mm at the cover top- Digital pH meter (portable)

- 200 liter external tank

- Cart for 200 l tank

- WinKratos S/W

Key Features

The range of Corrosion Test Chambers includes 3 models: 600, 1000 and 1200 liters. Traditionally specialized in “underfilm scab” and “filiform” corrosion tests, ACS chambers can also perform traditional salt spray tests (continuous, alternating, etc.) in compliance with the main international standards and regulations. VDA, SAE J2334 and the Kesternich test are available as standard options.

BENEFITS

- High-resolution dosage and high-precision spraying of the saline solution (atomization).

- Fully-transparent hood with servo-assisted opening (600-1200 l) or pneumatic system for handling (2300 l).

- Automatic stop of the running test in case of unintentional opening.

- Regulating-valve manometer for the control of compressed air flow.

- Flowmeter for the reading of the saline solution flow.

- VDA (with or without cooling unit) and SAE J2334 tests are available as options.

- On request the chamber can carry out tests according to the main Test Standards.

Configuration

- Lucite (Plexiglas) nozzle

- Rain gauge

- Pump for regulating the salt solution flow rate

- Flowmeter for reading the salt solution flow rate

Options

- Additional portholes: 100mm, see drawing for available positions.

- Wheels: wheels complete with feet (600 – 1200 l)

- PT100 additional probe: max. 3

- Rack for specimens

- Rods for specimens: wood rods (600 – 1200 l)

- Compressed dehumidification kit

- Graphic recorder: 6-channel microprocessor-based recorder

- Digital pH gauge: portable gauge

- Additional external tank: 200-liter capacity

- Cart with wheels for tank

- Air compressor demineralizer: single-column system

- Max. temperature +60°C

- Salt solution tank heater (according to JIS Z 2371)

- Software WinKratos™ for single-chamber remote control

- Software WinKratos™ for multichamber remote control, max. 16 chambers

- Wetting test: temperature control in a saturated environment with water bath heated at the bottom of the testing space.

- VDA test with cooling unit: water bath temperature at the bottom of the testing space is controlled by an external cooling unit. The external fan provides for air circulation inside the chamber. The air circulation system is a closed loop. This configuration includes the following option:

- Wetting test

- SAE J2334 test: this configuration includes the following options:• Max temperature +60°C• Wetting test• Kesternich Test (600 -1200 l) according to DIN 50018: dedicated line for SO2 inlet.

Customised Solutions

ACS has an extensive experience in the design and production of special chambers for corrosion testing, mainly for the automotive industry. The advancement of corrosion test applications in the automotive field has led to the launch of new special testing benches, in which alternate exposure conditions cause more severe effects on the products under evaluation.

Indeed, there are other conditions than just a salty atmosphere at play in the real-life use of vehicles, and these increase and worsen the effects of salt corrosion. Whole vehicles or single components can be subjected to an alternation of high and low temperatures, wet and dry conditions, and direct salt solution washing (i.e. splash test, salt rain) within a complete cycling test lasting many weeks.

Walk-in corrosion chambers

Walk-in chamber for corrosion tests combined with wind simulation

Test chamber for the accelerated aging of high voltage isolators: temperature, humidity, sun light, salt spray.

Control System

WinKratos is the software developed by ANGELANTONI Industrie S.p.A. for the monitoring and supervision of ATT climatic chambers through a PC (at customer care or on request), running under Windows (XP/VISTA/7 Professional version or higher).

Through WinKratos it is possible to create test profiles (programs), launch or interrupt the execution of a test in “manual” or “program” mode, display data in table or graphic form, and generate a report showing test results.

The software is designed to control not only single chambers but a whole test lab. It can then later be “scaled” and updated, if new machines are added to existing ones, with minimal impact in terms of time and resources.

Software Winkratos Multichambers

Main Features

- Connection of chambers of any type, by different kinds of interface in order to meet specific customer needs about distance, noise, etc… (Rs232, 485, 422, Ethernet)

- Colour printing on any kind of printer;

- Multiple access, password level.

Graphic Functions

- Fully-configurable layout of acquired measures’ charts;

- Display of several charts on the monitor;

- Several colours to be chosen at one’s choice for the display of different parameters’ curves;

- Enable/disable of chart display and grids;

- Real time update of acquired measures’ charts.

Operating Functions

- Create test programs;

- Refer to and modify previously created test programs;

- Delete all test programs that are no longer necessary;

- Print any test program in text format.

Acquisition Functions

- Real-time measurements of test parameters by means of graphic cursors;

- Maximum flexibility for cycles to be set;

- Storage of occurred events such as alarms, commands, etc…

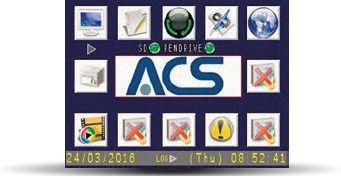

KeyKratos Plus

Based on a PLC structure, the system has a control panel consisting of a color touchscreen which allows the setting of all the necessary parameters for performing automatic and cyclical tests.

Main Features

- 5.7” touchscreen, 65,536 colors, TFT technology (faster control)

- 3 types of memory support for storing cycles, recordings, and alarms: Memory Board, Pendrive (USB key style), internal memory

KeyKratos – Main window

KeyKratos – Main window KeyKratos – Main control parameters

KeyKratos – Main control parametersSoftware

Control System

The chamber is equipped with a PLC (Programmable Logic Controller) for managing all the chamber’s functions and safety interlocks.

The chamber basic control is supplied by Weazy™, a very flexible HMI accessible on the 7 inch on board display.

WinKratos (optional) allows the complete management of the chamber functions: from manual control to the creation (through the graphic editor) of test profiles, including monitoring and recording, processing, graphical representation and analysis of data.

Weazy™ main features:

- Ethernet connection to the chamber

- Visualization of measures and recordings

- High configurability of chamber parameters

- Program and Manual chamber operation modes

- Delayed start of a program

- Automatic notifications of events and alarms

- 7 days data storage

- System available in several languages

Software drivers can be provided on request that allow you to manage the chamber directly from applications created by the customer.

Precision Starts Here